-

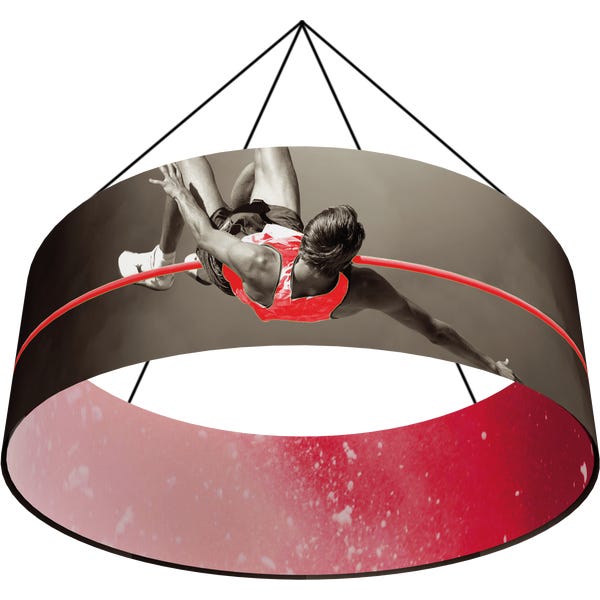

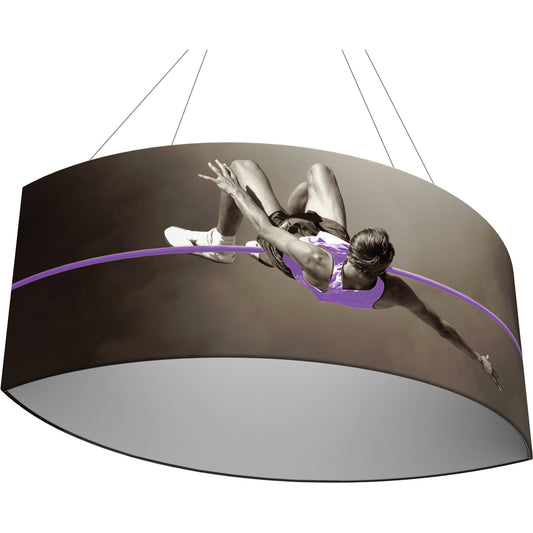

Vendor:Formulate® Essential

Ring · 10′ × 4′

Regular price From $2,069Regular priceUnit price per$0Sale price From $2,069 -

Vendor:Formulate® Essential

Ring · 10′ × 3′

Regular price From $1,799Regular priceUnit price per$0Sale price From $1,799 -

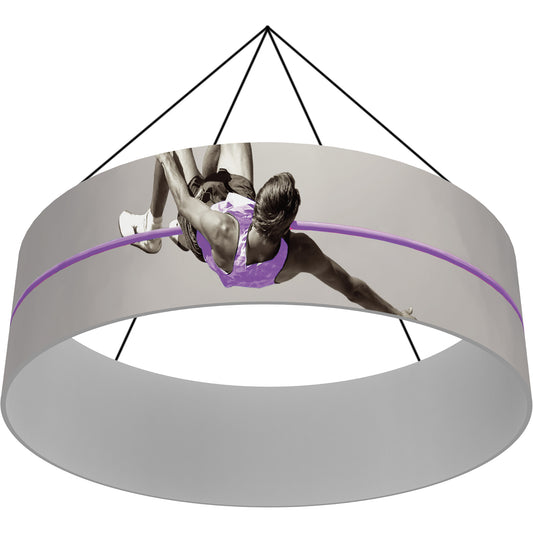

Vendor:Formulate® Essential

Ring · 8′ × 3′

Regular price From $1,479Regular priceUnit price per$0Sale price From $1,479 -

Vendor:Formulate® Master

Curved Panel · 10′ × 3′

Regular price From $959Regular priceUnit price per$0Sale price From $959 -

Vendor:Formulate® Master

S-Curve · 10′ × 4′

Regular price From $999Regular priceUnit price per$0Sale price From $999 -

Vendor:Formulate® Master

Flat Panel · 10′ × 2′

Regular price From $749Regular priceUnit price per$0Sale price From $749 -

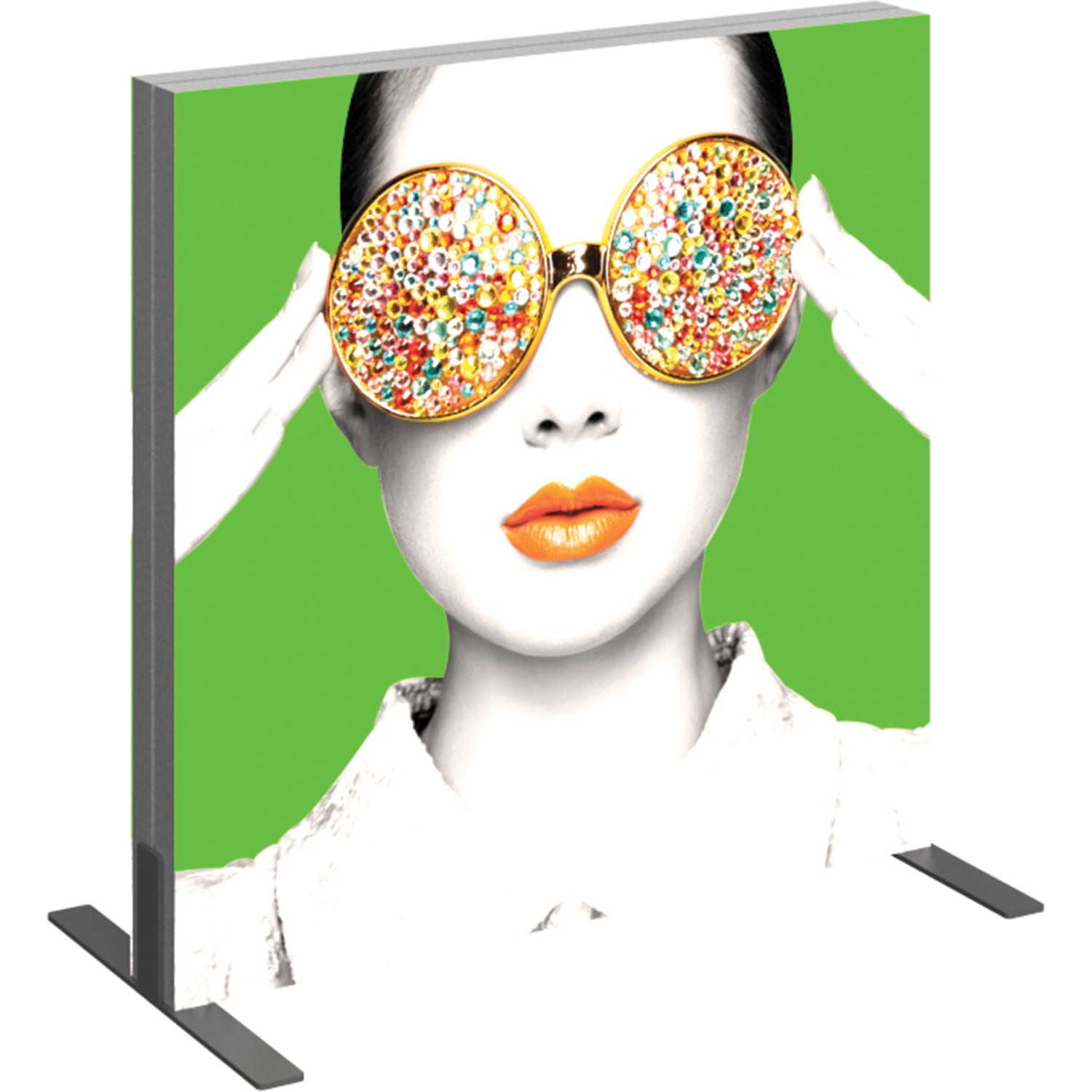

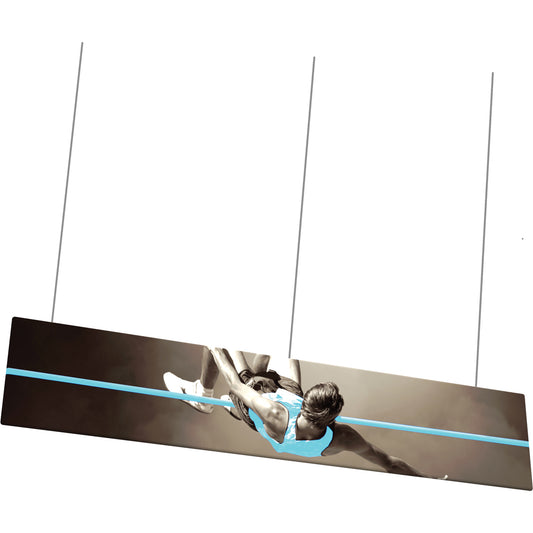

Vendor:Formulate® Master

Cube · 6′ × 6′ × 6′

Regular price From $3,729Regular priceUnit price per$0Sale price From $3,729 -

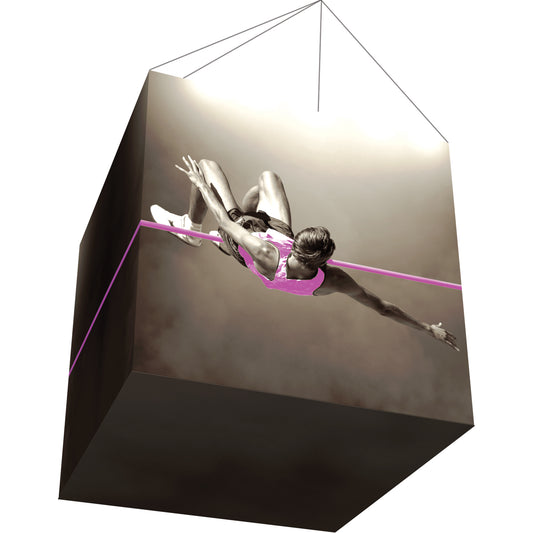

Vendor:Formulate® Master

Hexagon · 10′ × 4′

Regular price From $2,719Regular priceUnit price per$0Sale price From $2,719 -

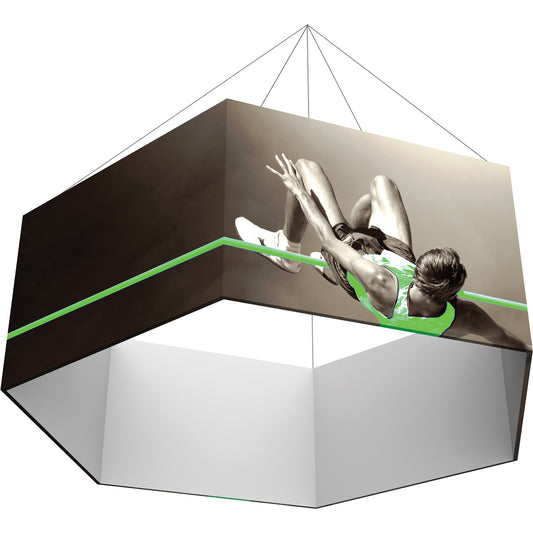

Vendor:Formulate® Master

4-Sided Pyramid · 10′ × 4′

Regular price $5,559Regular priceUnit price per$0Sale price $5,559 -

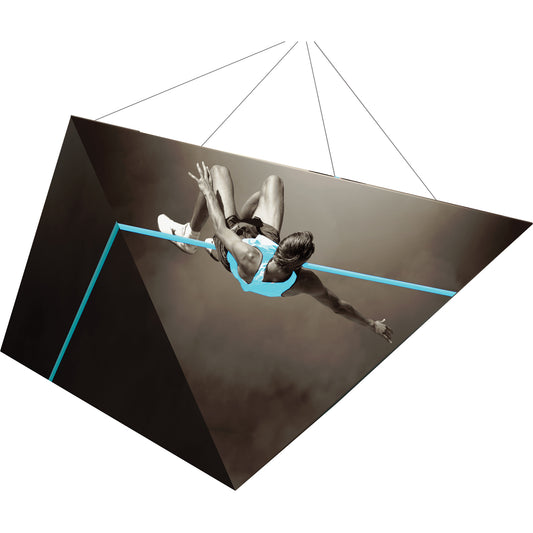

Vendor:Formulate® Master

Football · 10′ × 4′

Regular price From $1,739Regular priceUnit price per$0Sale price From $1,739 -

Vendor:Formulate® Master

Rectangle · 10′ × 4′

Regular price From $2,309Regular priceUnit price per$0Sale price From $2,309

Have a question? Contact us